PRODUCTS

PT. Royal Teknindo provides complete solution for all your hose and fittings requirements. With comprehensive lines of durable and dependable hoses, we provide products suitable for nearly any application, pressure level and type of fluid. The wide selection of hose options is complemented by an equally diverse and robust selection of fittings; which are precision-made and manufactured to the highest quality, available in numerous sizes and configurations.

PT. Royal Teknindo provides complete solution for all your hose and fittings requirements. With comprehensive lines of durable and dependable hoses, we provide products suitable for nearly any application, pressure level and type of fluid. The wide selection of hose options is complemented by an equally diverse and robust selection of fittings; which are precision-made and manufactured to the highest quality, available in numerous sizes and configurations.

PT. Royal Teknindo customers can choose one of several options when considering the product for their needs, namely:

1. Buying high quality products with high prices; or

2. Satisfied with low quality products offered at a price that is cheaper.

Therefore, management decided to work with manufacturers and distributors to provide wide range of products & brands with competitive price and high quality on the market today.

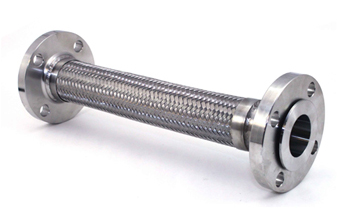

I. CORRUGATED METAL HOSE & FABRICATION

Corrugated metal hose is manufactured in a size range 1/4 inch (DN6) to 12 inches (DN300). Corrugated flexible stainless steel hose and tubing is available unbraided for general use or single/double braided to withstand greater pressure and vibration and for protection from abrasive attack.

Metal hose is made from several different materials, depending on application. When selecting the material, proper consideration must be given to corrosion resistance, service temperature and material strength. Components typically found in a metal hose assembly include corrugated flexible hose, one or more layers of wire braid, braid sleeves, fitting(s) and optional flexible guard and/or liner.

Metal hose is made from several different materials, depending on application. When selecting the material, proper consideration must be given to corrosion resistance, service temperature and material strength. Components typically found in a metal hose assembly include corrugated flexible hose, one or more layers of wire braid, braid sleeves, fitting(s) and optional flexible guard and/or liner.

When selecting fittings for a metal hose assembly, care must be taken to ensure that the material and construction of the fittings permit them to be welded to the hose, and are compatible with the application and the existing piping system.

As with the corrugated hose, the maximum allowable working pressure of the fittings must be derated for elevated temperatures. Whenever possible, it is advisable to use a swivel, floating, or axially disconnectable fitting on a least one end of the hose assembly to avoid torsion during installation. Some fittings (e.g. fixed flanges, elbows, etc.) require specific orientation on the hose assembly in order to be properly installed into the piping system.

II. HYDRAULIC HOSE, FITTINGS, ADAPTERS & ASSEMBLY

Hydraulics allow the transfer of energy through an incompressible fluid (liquid), this gives a very high power density. Hydraulic hose assembly is a conduit to transfer energy from port-to-port or point A to point B within a hydraulic circuit.

Hydraulic hose assembly consists of a Flexible hose with fittings at each end. Hydraulic hose and fittings products were developed to offer complete and consistent hydraulic coverage for all major industries worldwide.

Hydraulic hoses are constructed of three main components, Tube, Reinforcement and Cover. The inner most part of the hydraulic hose is the tube, wrapped up by reinforcement, which is encapsulated with a cover.

With so much international equipment now on the job site, a top-quality hydraulic hose is no use if we don’t have the right couplings to go with it. Whether your equipment is made in Japan, Germany, the United States, or elsewhere; we have hose and fittings products to fit your EN/DIN and SAE standards application needs.

The combination of a hose and hose fittings to make a hose assembly, is a critical process that needs to be carried out by professionally trained personnel who follow strict assembly instructions. Improperly assembled hose fittings can separate from the hose and may cause serious injury or property damage from whipping hose, or from fire or explosion of vapor expelled from the hose.

III. INDUSTRIAL HOSE, FITTINGS & ASSEMBLY

Industrial hoses are manufactured with a wide variety of rubber, PTFE, PVC or thermoplastic compounds due to the wide variety of conveyed materials, solutions, and applications. The particular compounds and/or materials used for each industrial hose product depend on the specific application for each hose. In general, some advantages of industrial hoses are increased hose flexibility, the ability to produce long lengths, large bore capabilities and the ability of industrial hose to coexist with a wide range of end fittings and attachment methods.

Some typical applications for industrial hose are air & multipurpose hose, water suction and discharge hose material handling hose, specialty service hose, food industry and transfer hose, acid and chemical service hose, petroleum service hose, steam service hose and etc.

Some typical applications for industrial hose are air & multipurpose hose, water suction and discharge hose material handling hose, specialty service hose, food industry and transfer hose, acid and chemical service hose, petroleum service hose, steam service hose and etc.

Industrial hose fittings refer to the end connection of an industrial hose and how it is attached. These fittings are used in variety of applications. Fittings could be referred to as quick connect, flanged, threaded, Boss or barbed. The choices are many and the construction could be steel, brass etc. Proper selection should be made to accommodate specific applications.

Attachment of end fittings vary from worm gear clamps, superior clamps, double bolts clamps, Boss clamps, safety aluminium clamps or crimped ferrules. Proper selection should be made to accommodate working pressures, vacuum and the external environment they are exposed to.

APPLICATION

1. Industrial ( Automotive, Chemical, Electrical, Oil & Gas, Pulp & Paper ).

2. Ship & Marine Commercial.

3. Mining & Construction.

4. Forestry & Agriculture.

5. Material Handling.

6. Machinery & Machines ( Special Product Applications, General Engineering, OEM Engines ).